Vacuum impregnation

【Quality and Environmental Policy】

Through vacuum technology, our company provides customers with reliable, excellent quality and places its core values on environmental preservation that is friendly to people and the earth. We fulfill our corporate social responsibilities and seek to improve credibility and trust.

※ We set goals for Q, C, D, and S and do our best for continuous improvement.

Q (Quality: Quality improvement)We strive to improve quality and protect the environment by continuously improving our integrated management system.

C (Cost: cost reduction)

We strive to carry out energy-saving and resource-saving activities, suppress the generation of industrial waste, and provide environmentally friendly products.

D (Delivery: Compliance with delivery date)

We do our best to meet customer needs.

S (Safety: Ensure safety)

At each stage, we aim to improve preventive activities.

※ To achieve the above quality environmental policy, we commit to the following

⊙ We continuously improve our quality and environmental management system.⊙ We develop the quality policy and environmental policy into quality goals and environmental goals and manage them to achieve those goals.

⊙ We pursue the reliability, durability, and operability required by our customers, and at the same time, manufacture them to suit the customer's purpose and application. (Support for special specifications)

【Overview of impregnation】

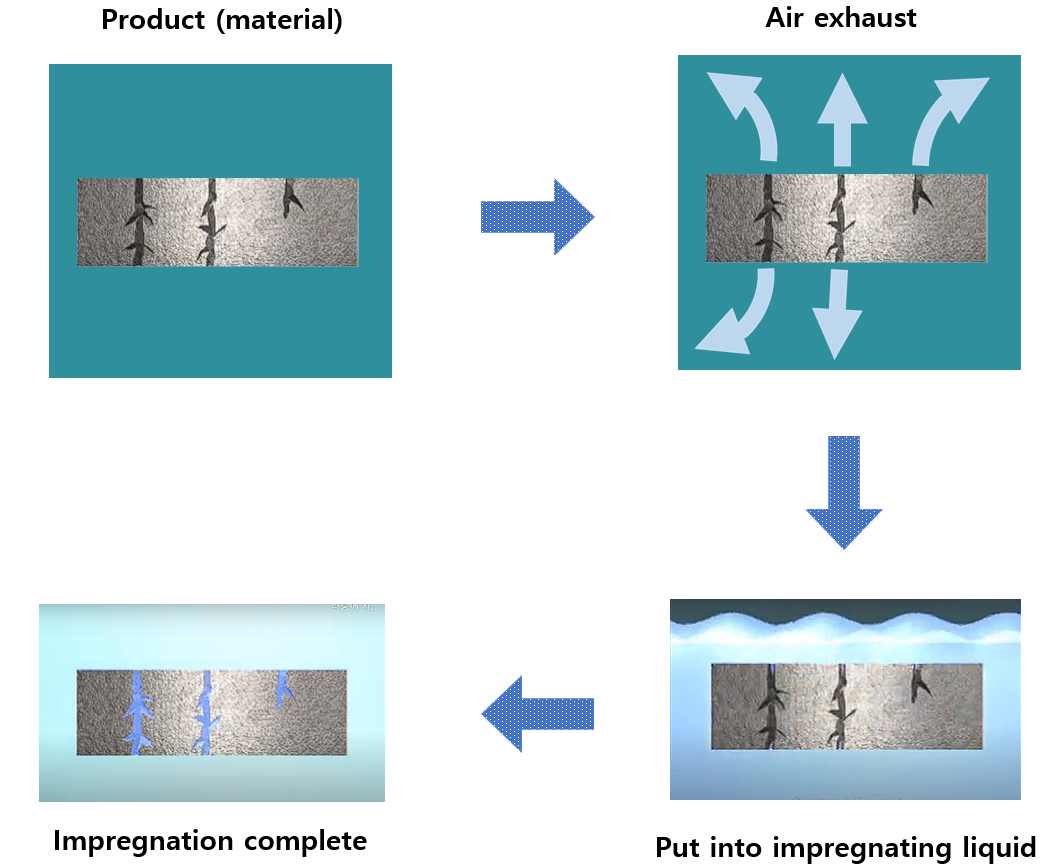

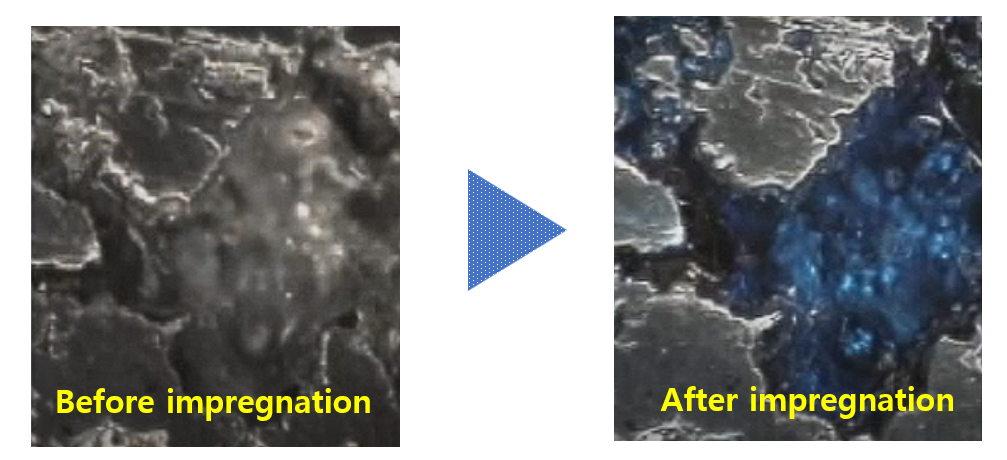

Impregnation is a technology that immerses liquid into the gaps inside the material.

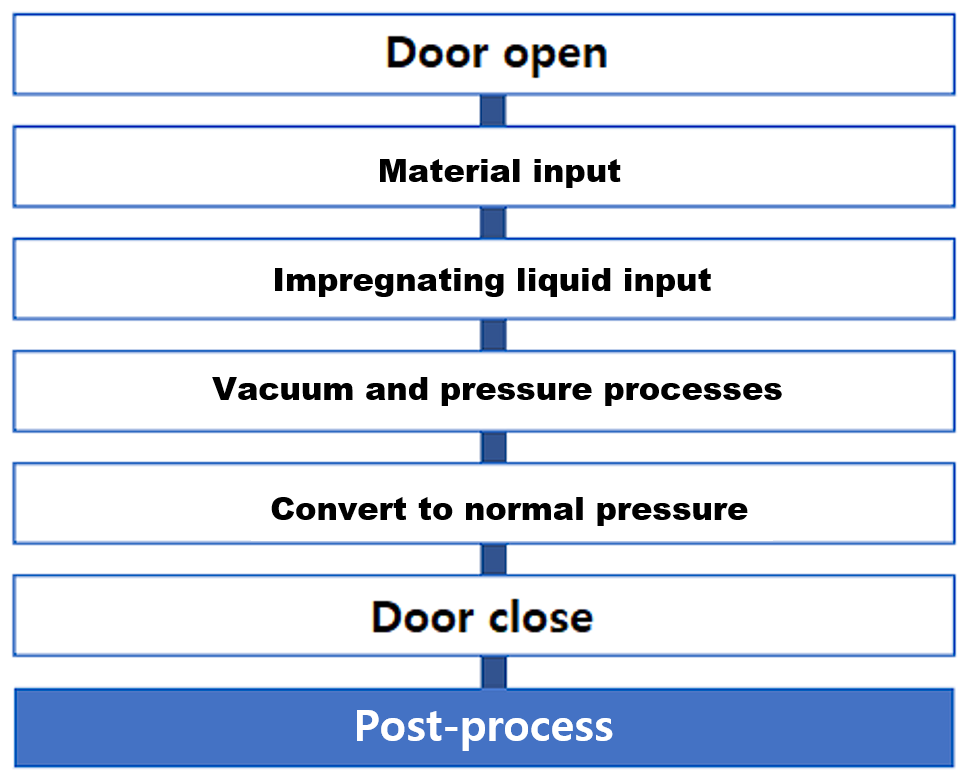

By placing a material in a processing container (tank) and placing it in a reduced pressure environment, the air bubbles inside are removed, liquid is injected into the tank to impregnate it, and then further pressurized to rapidly penetrate the gaps inside the material.

Various impregnation treatments are used to maintain airtightness and prevent corrosion of metal, wood, and resin, as an insulating layer in motor coils, and in food and electronic components.

The main methods are “vacuum impregnation,” which uses a vacuum to infiltrate liquid, and “vacuum pressure impregnation,” which applies pressure after vacuum impregnation.

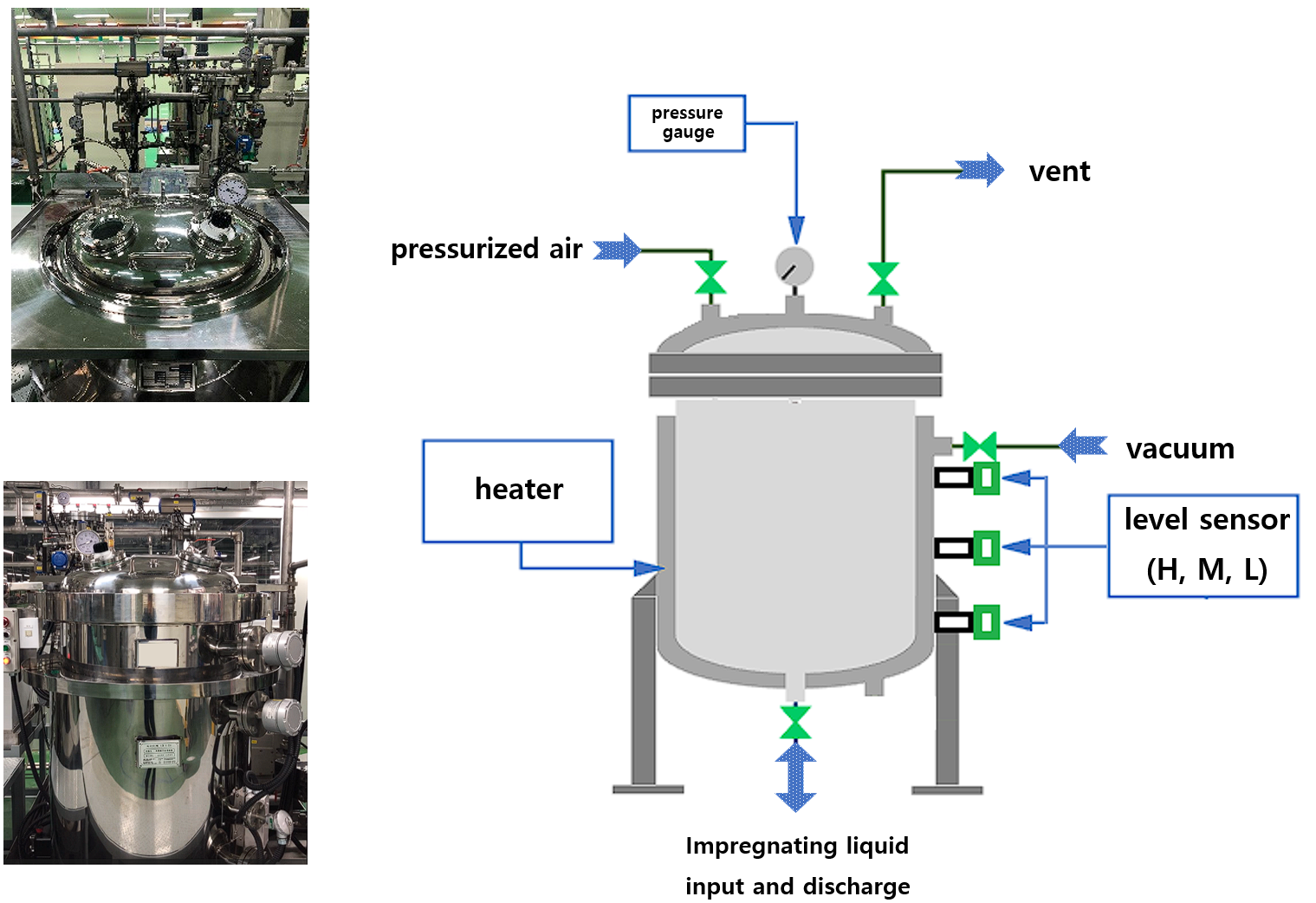

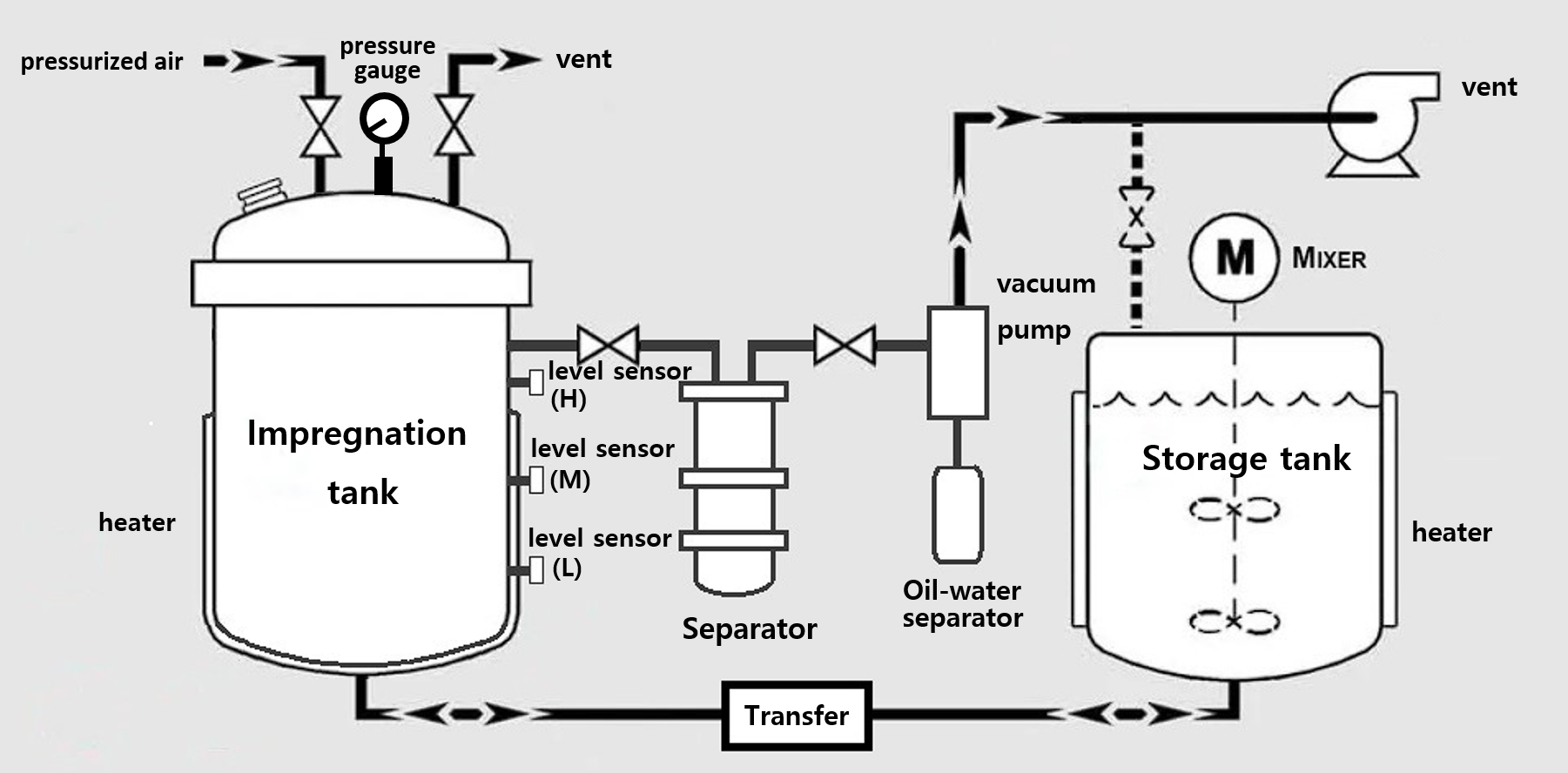

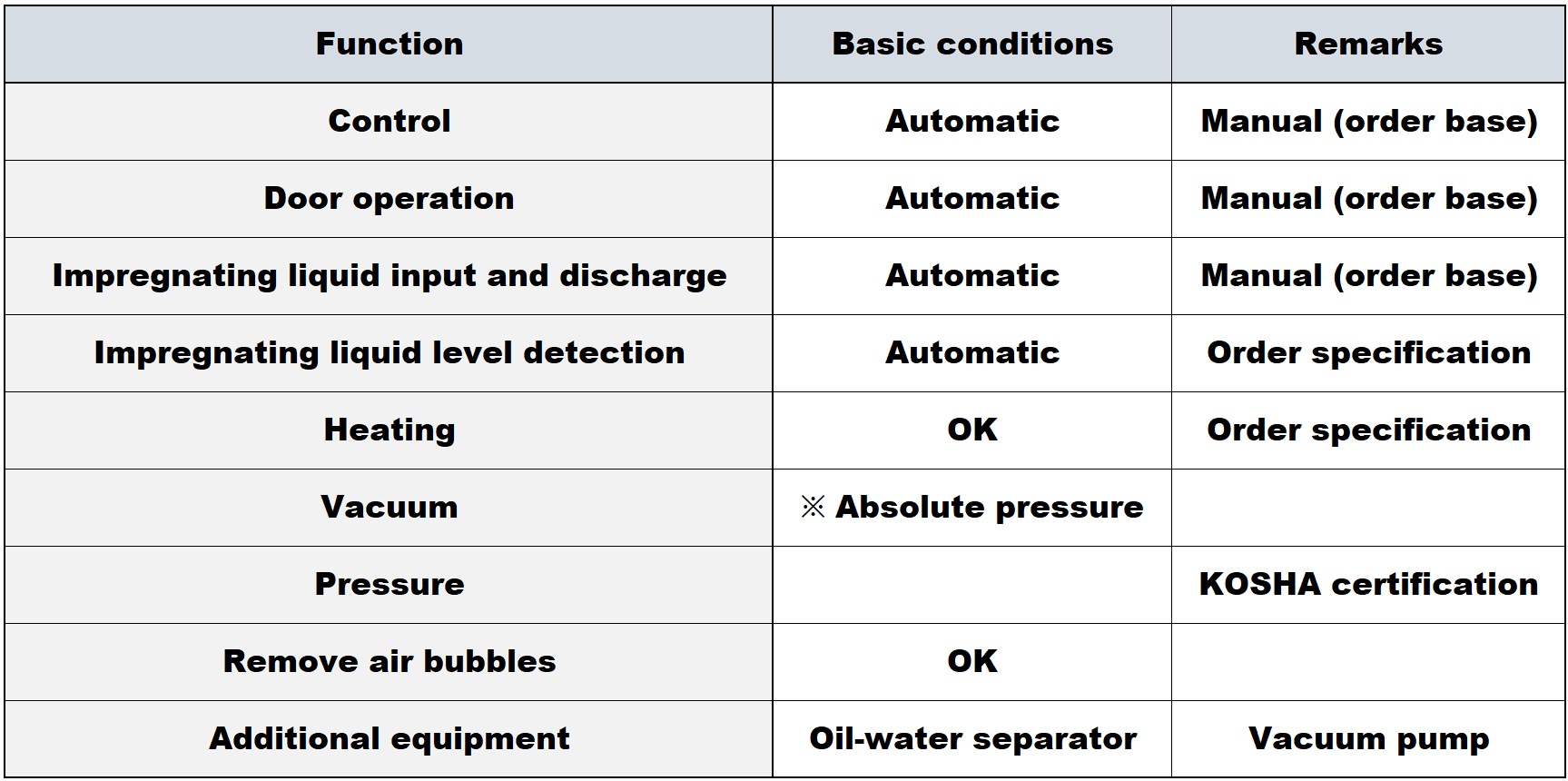

【Example of impregnation tank production】

This is a case where electrolyte impregnation is carried out in a pressurized and vacuum tank for condensers, batteries, etc.

( ※ Impregnation tank specifications and line configuration are determined depending on the purpose of use and conditions of the impregnated object. )